What is PCM ?

Phase Change Material (PCM) is used in cold chain to provide advanced thermal protection for temperature sensitive products during transit or storage.

Phase Change Materials are substances that absorb or release heat energy by freezing and melting at defined temperatures. Phase Changes are reversible.

A Phase Change takes place when a substance changes from it's Liquid phase to it's Solid phase (freezes or crystallises), and again when the substance changes back to it's Liquid phase (melts).

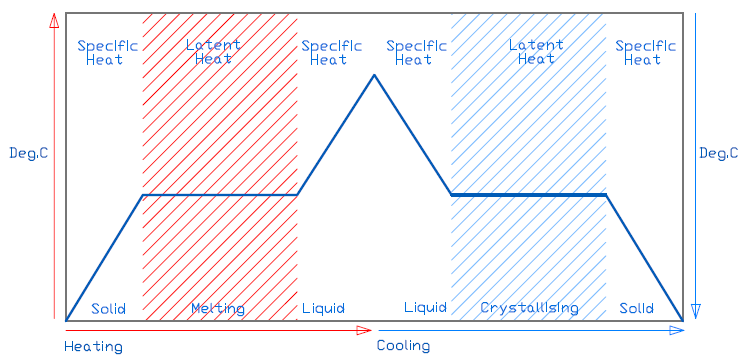

When a liquid is heated and no Phase Change takes place, it's stored thermal energy increases as its internal temperature rises. This energy is called “Specific Heat”.

When a solid is heated, and Phase Change does takes place, its internal temperature will remain the same until the solid has melted, and it's stored thermal energy has been released. This is called “Latent Heat”.

Water is the oldest and most common Phase Change Material, so let us first refresh our understanding of Heat Transfer, then look at what happens when Phase Changes occur with water and ice.

Water – the oldest & most common PCM (1).

Place a glass of water in the sun. The water molecules get excited, and the temperature increases, so does its stored energy.

Water – the oldest & most common PCM (2).

lace a glass of ice cubes in the sunlight and the ice will start to melt. The temperature will stay at 0oC until ALL the ice has melted.

The Phase Change Cycle

When a PCM is in its solid or crystallised state, it must be heated before it will reach it's Phase Change Point, and when in its liquid state, it must be cooled before it will reach it's Phase Change Point.

Phase Change Materials are ideal where controlled storage and release of Thermal Energy is required.

PCM's act like a battery because they absorb thermal energy as they melt, and can be “re-charged” by cooling them to their solid or crystalline state, giving the stored energy back to their initial environment.

PCM's can store and release energy thousands of times without effecting their thermal properties.

Phase Change Materials - 1

Water has a high latent heat capacity, why not use just water?

Water does have a high latent heat, but it melts and freezes at 0oC. So for many cold chain solutions, the melting temperature is either too high or too low.

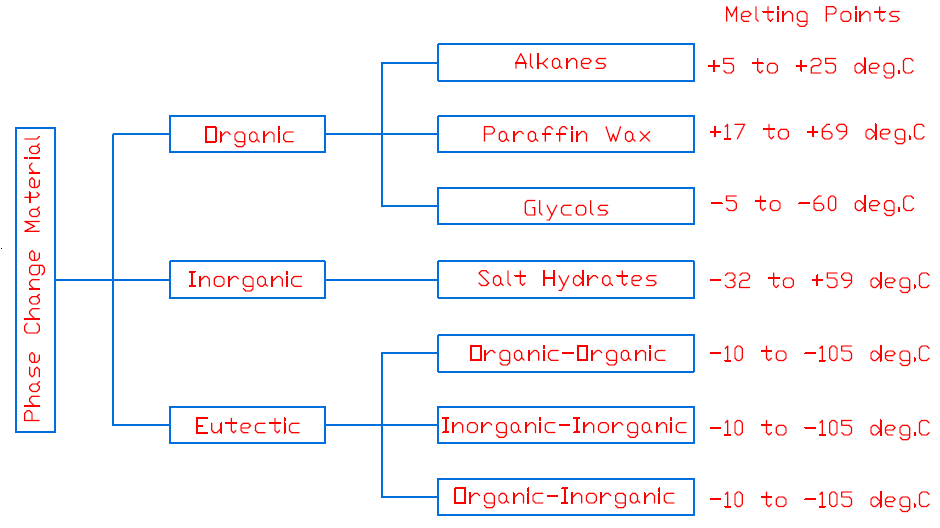

The PCM's that Haotian uses fall into three chemical groups:

1. An organic compound is formed as a result of actions of living organisms (biological in nature). An organic compound contains one or more carbon atoms which are bonded to hydrogen atoms by a hydrogen-carbon bond.

2. An Inorganic compound is formed due to natural processes unrelated to any life form (mineral in nature), and does not contain bonded hydrogen and carbon atoms.

3. An Eutectic compound is formed by two or more organic, inorganic or organic-inorganic components in such proportions that their combined melting point is equal to the lowest melting point of any component.

In a chemical formula, the number of atoms of each element, if more than 1, is written as a subscript (H20).

What is a “molecule”? A molecule is the smallest particle in a chemical element or compound that has the chemical properties of that element or compound.

What is an “atom”? An atom is the smallest possible unit of an element. Atoms are the basic building blocks of matter because they cannot be divided into smaller particles by any chemical process. An atom consists of three types of sub-atomic particles – neutrons, protons and electrons.

Phase Change Materials - 2

The Melting Temperature of a PCM should be close to midway between the highest and lowest safe temperatures. For example for PCM+5, for +2 to +8 deg.C protection, the Melting Point is 5.6 deg.C.

PCM's offer a wide choice of Melting Points.

Guidelines for PCM

If a PCM plate has a large surface area and a small volume, the PCM will melt faster, but keep the payload colder.

If a PCM plate has a small surface area and a large volume, the PCM will take longer to melt, but the payload will be not be as cold.

For the longest cold life, the flow of heat energy inside the cold space from the payload (remember that heat energy flows from hot to cold!) to the PCM, must not be blocked or restricted.

If a client requires a frost barrier between the payload and the PCM, it should not interfere with the flow of heat energy. The best frost barrier to use is PE packing foam, maximum thickness, 3mm. This has negligible thermal resistance.

If low performance is reported, check -

1. The Client's pre-conditioning procedure

2. Packing out, payload and ambient temperatures

3. The plate filler for leaks or tampering

4. The PCM for undissolved solids or gelling

5. The condition of the PolarBox, in particular: the lid fit; swelling of side, top or bottom panels; and cracks in the corners

Obtain a PCM plate from the Client for checking the SG, Melt Cycle, Latent Heat and Chemical Properties of the PCM.

English

English  français

français русский

русский italiano

italiano español

español português

português العربية

العربية 日本語

日本語 한국의

한국의 magyar

magyar